top of page

BENEFITS: Creating Value

Goal: Increase Good Parts per Hour

Improve Productivity:

-

Reduce Cycle Time

-

Decrease Die Solder

-

Accelerate Process Development

Reduce Costs:

-

Reduce Warm-Up Scrap

-

Improve Quality

-

Cut TCU Energy Costs

Our Thermal Control System Results:

Typical financial breakeven in <6 months. Factors to consider:

-

Thermal Quality Issues (solder, leak test failures, shrink porosity, start-up scrap, etc.)

-

Die cooling design and facility cooling capacity

-

Quantity of TCUs used

Thermal Control Methods

Die Therm's data will identify the thermal constraint(s). Collaborate with customer to address constraints.

Identify Thermal Contraints

-

Die Cooling Power vs. Cooling Capacity

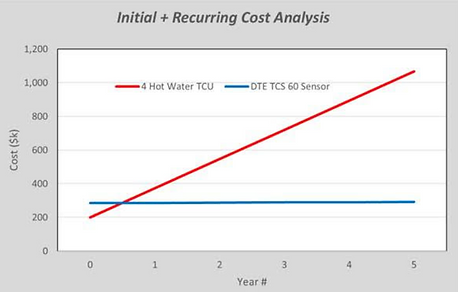

Initial & Recurring Cost Analysis

Life Cycle Costs should consider the annual energy costs.

Example Compares:

(4) Hot Water TCUs vs (1) 60-sensor Die Therm system

Annual Electrical Cost:

HW TCU: $44k/TCU

DTE 60: $1.5k

Breakeven:

0.49 years

bottom of page